Phasics

- Wavefront, MTF and QPI measurement solutions

- Products

- Applications

- Markets

- Company

- Contact us

Feb. 9, 2026

What are GRIN Materials?

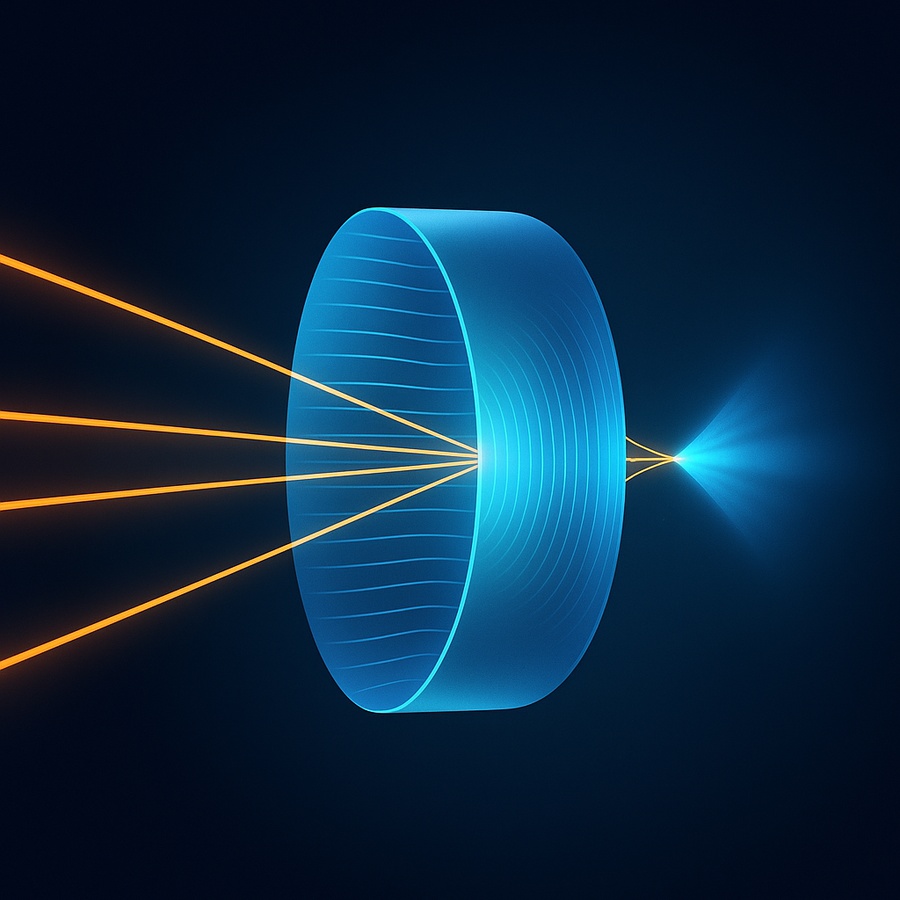

Gradient-index (GRIN) optics rely on a continuous variation of refractive index within a material to control light propagation. Unlike conventional optics, where beam shaping is primarily achieved through surface curvature, GRIN components guide and focus light through internal refractive index gradients. Light rays naturally bend toward regions of higher refractive index, enabling compact optical designs with reduced aberrations.

Figure 1: Left: Conventional lens. Right: GRIN lens.

A Gradient-Index Lens (G-lens) is a classic example of a GRIN component. These elements typically exhibit a radial refractive index profile that approximates a parabolic distribution, allowing smooth beam convergence within the material itself. Compared with traditional spherical lenses, G-lenses enable more compact optical paths, reduced wavefront distortion, and strong compatibility with fiber-based or miniature optical systems. These advantages make them ideal for space constrained applications like laser collimation, medical endoscopes, and fiber coupling,etc.

The Challenge of Infrared GRIN Optics

While GRIN technology is mature in the visible and near-infrared spectral regions, extending it into the mid-wave and long-wave infrared (MWIR/LWIR, 3–14 µm) remains a significant challenge. Manufacturing limitations have historically restricted the development of lightweight, high performance infrared GRIN materials, leaving a gap between theoretical designs and practical implementation.

A recent study published in Advanced Functional Materials introduces a new fabrication approach based on rapid Na⁺/Ag⁺ ion exchange in chalcogenide glass. The material composition (0.72GeSe₂–0.28Ga₂Se₃)₇₅(NaI)₂₅ was selected for its strong infrared transmission properties.

The process involves an initial solid state ion exchange using a KNO₃ and AgNO₃ powder mixture at 250°C, followed by thermal annealing at approximately 310°C to drive radial diffusion of silver ions toward the core. This solid state approach avoids corrosion issues associated with molten salt baths while significantly accelerating diffusion. The reported results show that Ag⁺ ions reached the center of a 10 mm sample in under 27 hours, achieving a refractive index change of approximately Δn ≈ 1.8 × 10⁻¹ at 10.6 µm.

Quantitative Validation through Wavefront Metrology

Precise characterization of the refractive index gradient is essential to validate optical performance. In the infrared domain, conventional interferometric techniques can be limited by system complexity and stability requirements.

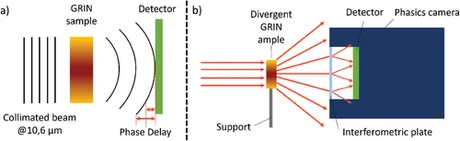

To address this challenge, the research team employed the Phasics SID4-DWIR infrared wavefront sensor. Based on Quadriwave Lateral Shearing Interferometry (QWLSI), the system enables direct phase measurement without scanning or complex fringe processing.

Using a CO₂ laser (λ = 10.6 µm) as the source, researchers recorded the Optical Path Difference (OPD) of the samples:

Fig. 2 (Left) Experimental optical setup schematic. (Right) OPD distributions of samples with different annealing durations under CO₂ laser illumination. Image source: Advanced Functional Materials (Wiley, 2024)

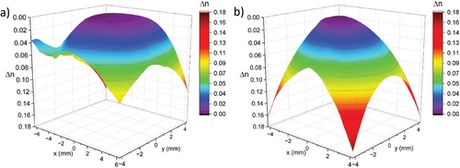

Fig. 3 Three-dimensional optical path difference (OPD) distributions of two GRIN samples measured with the Phasics SID4-DWIR at a wavelength of 10.6 µm.

(a) Sample annealed for 6 hours: refractive index gradient concentrated near the edges, with a relatively flat central region, indicating incomplete diffusion of silver ions toward the core; maximum Δn ≈ 1.6 × 10⁻¹.

(b) Sample annealed for 24 hours: refractive index profile follows a quadratic distribution, showing diffusion of silver ions into the center and formation of a complete radial GRIN structure; maximum Δn ≈ 1.8 × 10⁻¹.

Image source: Advanced Functional Materials (Wiley, 2024)

By placing the sample close to the SID4-DWIR sensor, the team successfully mapped the high-gradient distribution, revealing a continuous refractive index profile that closely follows a quadratic polynomial.

Infrared Wavefront Metrology with SID4-DWIR

Phasics SID4-DWIR is a dualband wavefront sensor covering both the 3–5 µm (MWIR) and 8–14 µm (LWIR) spectral ranges, providing comprehensive measurement capability across key infrared windows. Designed for the characterization of infrared lenses, thermal imaging systems, and CO₂ laser sources, it integrates a 160 × 120 pixel sensor with 25 nm RMS phase sensitivity for quantitative wavefront analysis. Real-time acquisition is achieved without relay optics, even for high NA beams.

Figure 3 Phasics SID4-DWIR

Thanks to the research team, the study demonstrates how advanced wavefront metrology enables reliable evaluation of infrared GRIN materials and supports the development of next generation infrared optical designs.

Interested in high resolution IR wavefront sensing? Feel free to reach out to our team for a technical consultation or a demo.

Reference: Fourmentin C., et al. Advanced Functional Materials, 2024.